Liangjiang strengthens supply chain to fuel auto industry

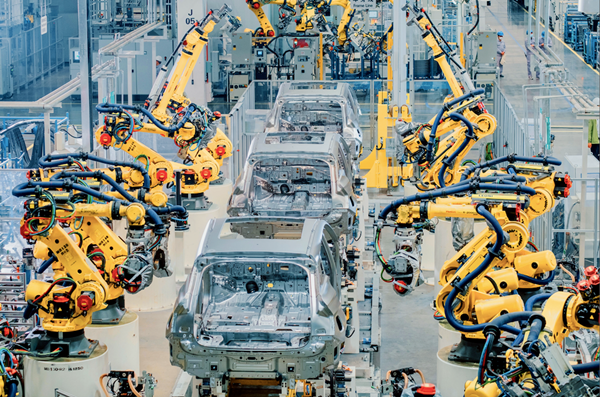

SERES super factory starts operation in Liangjiang New Area in February this year. [Photo/Xie Li]

Liangjiang New Area is experiencing a significant boost in its automotive industry, driven by a strengthened supply chain.

At the Chongqing Futurus Technology Co's factory, robotic arms efficiently produce intelligent heads-up displays, with three units rolling off the production line every 60 seconds.

Huo Quan, a company representative, noted that mass production enables Futurus to supply these advanced products to new energy car manufacturers in the region.

Liangjiang is home to 23 intelligent connected auto suppliers, including Futurus, that supply essential components such as automotive-grade chips, millimeter-wave radar, and in-vehicle systems.

A local official noted that this robust supply chain enhances the capabilities of local car manufacturers and supports the industry's capacity upgrades.

The area can produce all mainstream new energy vehicles, including pure electric, range-extended electric, and hydrogen fuel vehicles. Most major products now achieve Level 2 automated driving (partial driving automation) or higher.

The average price of new energy vehicles (NEVs) manufactured in Liangjiang has risen to 226,000 yuan ($31,747.04), shifting towards the high-end market. The SERES AITO M9, for example, leads the market for models priced over 500,000 yuan, with more than 15,000 deposits since its launch. In the first nine months of this year, SERES sold 316,713 NEVs, a fourfold increase from last year. Changan Auto, another major automaker in Liangjiang, sold 447,618 NEVs.

Liangjiang has introduced measures to manufacture over 1.2 million cars this year, including more than 500,000 NEVs, and achieve an output value of 200 billion yuan in the auto industry.