Donghai Island, a rising titan in the heavy chemical industry in Guangdong

Aerial photo of Zhanjiang Steel Base of Baosteel Co [Photo by Liu Jicheng/southcn.com]

Located near the southernmost tip of the Chinese mainland, Donghai Island of Zhanjiang, the largest island in Guangdong province, has now become the main battlefield for the development of the heavy chemical industry in the province and even the whole country.

The island has attracted three main projects with an investment of tens of billion yuan each, including Zhanjiang Steel Base of Baosteel Co, the China-Kuwait refining-chemical integration base and the Zhanjiang production base of BASF SE. These three projects have made Donghai Island an industrial cluster of world-class green high-end coastal heavy chemical industry focusing on high-end manufacturing, intelligent manufacturing and green production.

High-end manufacturing

The advanced technology and the lower cost enable Baosteel Zhanjiang branch to not only fill in the blanks in the production base in Guangdong, but also meet the development needs of Guangdong's automobile, home appliance, machinery and other industries, form a reasonable matching of the industrial chain, and even benefit the Southeast Asia market.

The China-Kuwait refining-chemical integration base aims at becoming a world-class project with a top design. Its product performance is expected to reach an internationally-leading level and replace a large number of imported products.

The BASF Chemicals Integration Base is actively building new engineering plastic modification devices, with the expectation of producing more than 40 products in the future, which are mainly going to be sold to Guangdong and South China markets.

Intelligent manufacturing

At present, 61 sets of robots have been put into use in the Zhanjiang steel base of Baosteel. The 20 piles and reclaimers of the raw material yard have completed unmanned remote operation, and the coke ovens have also realized unmanned operation. In the warehouse, 20 sets of production vehicles were unmanned, and two sets of automated packaging units were built. Moreover, it has introduced the first 5G intelligent manufacturing production line in the province.

The global chemical giant BASF brings international vision. The Zhanjiang base of BASF is said to be BASF's first large-scale integrated production base for the full implementation of digital technology and intelligent manufacturing concepts. Digital technology and applications will be used to better manage energy and waste, and increase the use of renewable energy. Unmanned vehicles, robots, paperless operations and other technologies will be used to reduce human error and create better production conditions and capabilities.

Green production

Baosteel Zhanjiang branch has adopted about 116 reliable energy-saving and environmental protection technologies with an investment of over 6.5 billion yuan. In addition, two artificial wetlands have been set up at the base to treat domestic wastewater and coking wastewater separately, which can not only improve the ecological environment, but also the landscape within the plant.

The China-Kuwait refining-chemical integration base has also put efforts into selecting advanced production technology and practical treatment technology to minimize the impact of all pollutants on the environment. BASF is focusing on recycling plastic waste.

The gathering of the three companies in Donghai Island will create a whole industrial chain of steel and chemicals and drive development of an upstream and downstream industrial economic chain, as well as promote the entry of supporting enterprises for local infrastructure and utilities.

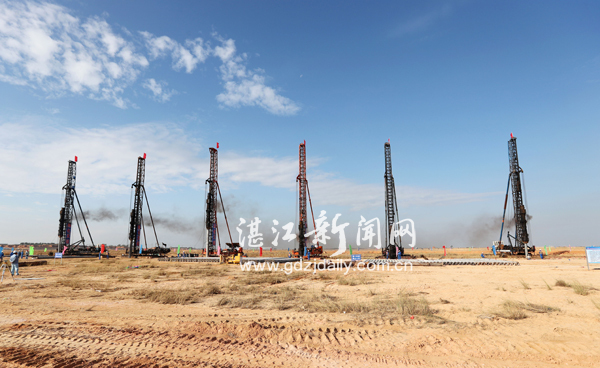

China-Kuwait refining-chemical integration base starts construction. [Photo by Lang Shuchen/gdzjdaily.com.cn]

MOST POPULAR

Editors' Picks

Infographic:

China's 5G subscriptions hit a new milestone

Infographic:

China's 5G subscriptions hit a new milestone

Database:

China Economic Data Tracker

Database:

China Economic Data Tracker

Infographic:

China extends visa-free transit to 240 hours

Infographic:

China extends visa-free transit to 240 hours